In today’s fast-paced and highly competitive business environment, supply chain automation has become a necessity rather than a luxury. As global supply chains grow increasingly complex, manual processes struggle to meet the demand for speed, accuracy, and efficiency. Addressing these challenges is crucial, and one of the most effective ways to do so is by leveraging cutting-edge solutions like Boomi for supply chain automation.

In an era where customer expectations are higher than ever, and market dynamics are constantly shifting, automating supply chain processes is essential for maintaining competitiveness, ensuring customer satisfaction, and fostering long-term business resilience. In this blog post, we will explore how Boomi can revolutionize supply chain automation.

What Is Supply Chain Automation?

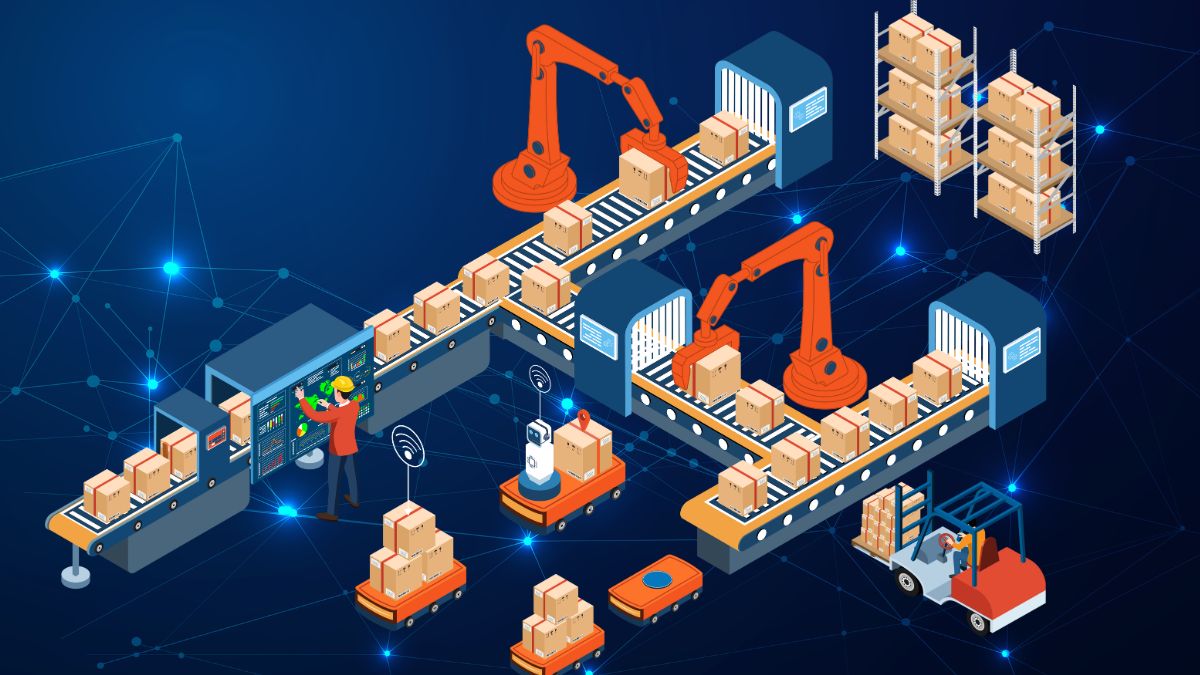

Supply chain automation involves using technology to streamline and restructure supply chain processes, reducing the reliance on human intervention. Automation can range from enhancing individual processes to creating smart factories equipped with technologies like the Internet of Things (IoT) and Artificial Intelligence (AI).

By interconnecting sensors, machines, and devices, businesses can create a more responsive and organized manufacturing ecosystem. Integrating manufacturing infrastructure enables practices such as predictive maintenance, reduced downtime, and minimal supply chain disruptions. Additionally, automation simplifies complex logistical tasks, from inventory management to order fulfillment.

One of the main advantages of automation is the reduced dependence on manual labor, which decreases the risk of human error. Implementing supply chain automation ultimately leads to greater visibility and control over logistics, resulting in better resource allocation, increased productivity, and cost savings.

Key Supply Chain Automation Technologies

Supply chain automation isn’t reliant on a single technology; it’s a convergence of multiple innovations aimed at solving challenges. Some of the key technologies include:

The Internet of Things (IoT)

IoT leverages sensor networks to track and monitor assets such as vehicles and inventory. Smart devices facilitate seamless data exchange and communication, improving operational efficiency.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML play a critical role in supply chain automation, particularly in predictive analytics, which forecasts future demand for products and materials. By analyzing vast datasets, these technologies enhance decision-making, optimize inventory levels, and improve adaptability to volatile market conditions.

Robotics and Automation in Warehousing

Robotic systems like Automated Guided Vehicles (AGVs) and robotic picking are transforming warehouses. These technologies automate order-picking processes and enhance material movement, boosting both safety and efficiency.

ERP Modernization and Cloud Integration

Moving processes and data to cloud platforms enhances manufacturing operations by providing better scalability and accessibility, ensuring smooth communication across different departments.

Electronic Data Interchange (EDI) Modernization

EDI enables automated document processing through standardized, structured data shared between vendors, manufacturers, and business partners. It improves communication efficiency, organizes data exchange processes, and fosters seamless collaboration within supply chains.

Application Programming Interfaces (APIs)

APIs facilitate interaction and data sharing between different applications. By automating unstructured data sharing between external and internal systems and business applications, APIs help maximize the potential of a technological ecosystem.

Challenges with Supply Chain Automation

If you’re considering automating your supply chain, you may encounter the following challenges:

Increasing Costs

Rising prices for fuel, raw materials, and labor—driven by energy costs, material scarcity, and higher wages—significantly impact operating costs.

Demand Fluctuations

Constant shifts in consumer trends and behavior make it difficult to predict sales and manage the supply levels needed, leading to risks of overstocking and inventory obsolescence.

Growing Need for Sustainability

As consumers become more conscious of the environmental impact of their purchasing decisions, businesses must revise production techniques and be transparent about their efforts to meet ESG goals to protect their brand reputation.

Gaps in Tech Stack

Disconnected technologies and process silos can impair supply chain visibility, making it challenging for supply chain managers to review performance effectively.

Benefits of Supply Chain Automation with Boomi

Embracing supply chain automation is vital for manufacturing companies serious about staying competitive. Boomi offers a robust platform to help your business scale. The Boomi platform connects supply chain vendors and customers, providing real-time visibility into demand, supply, inventory, shipping, invoicing, and more. Here are some key benefits of using Boomi for supply chain automation:

Automation of Manual Tasks

Boomi’s workflow automation capabilities streamline various supply chain processes. You can automate order processing, from receipt to fulfillment, reducing processing time and minimizing human errors.

Better Inventory Management

Boomi’s supply chain automation optimizes inventory levels, preventing shortages or overstock situations. This ensures effective resource allocation and minimizes holding costs.

Reduced Human Errors

Boomi’s automation capabilities minimize the risk of errors, enhancing overall operational efficiency and enabling a faster and more organized production cycle. Human errors that disrupt supply chains can result in significant losses, which Boomi helps mitigate.

Actionable Data Insights

Boomi’s integration capabilities create valuable data insights that support informed strategic decision-making. Analyzing data not only drives process improvements but also helps mitigate uncertainties by providing prior information.

Enhanced Supply Chain Visibility

Understanding operations across the entire supply chain allows companies to oversee the movement of products and components at each phase, ensuring better management and control.

Improved Customer Satisfaction

Efficient manufacturing processes enabled by automation result in timely and accurate order fulfillment. This leads to higher customer satisfaction and stronger relationships as products are delivered as promised.

How to Automate Your Supply Chain Management with Boomi

Automating supply chain management with Boomi involves leveraging its robust integration platform to streamline processes, enhance visibility, and improve efficiency. Boomi, a leading Integration Platform as a Service (iPaaS), enables seamless connectivity across various applications and data sources, making it ideal for supply chain automation. Here’s how you can get started:

1. Assess the Current Supply Chain

Identify pain points and bottlenecks in your current supply chain processes to understand where automation is needed. Evaluate your existing infrastructure, data management capabilities, and digital integration to ensure a smooth adoption of advanced technologies.

2. Choose the Right Automation Solutions

Determine whether custom or off-the-shelf automation systems are best suited for your specific needs. Carefully vet vendors and exercise due diligence to ensure the reliability and compatibility of the chosen solutions.

3. Integrate with Existing Systems

Ensure that your automation solutions integrate seamlessly with existing CRM, ERP, and other software. Address compatibility concerns and focus on data migration and interoperability to create an organized system.

4. Training and Change Management

Prepare your workforce for automation through change management and training initiatives. Focus on upskilling employees to equip them with the skills necessary for the new automated environment.

5. Scalability and Flexibility

As your business grows, Boomi’s scalable platform can adapt to increased data volumes and complex processes. Its flexible architecture allows you to easily add new integrations and workflows, ensuring your supply chain automation evolves with your business needs.

Conclusion

Boomi ensures compliance with industry standards and regulations through secure data integration and management. Automating compliance checks and audit trails helps maintain data integrity and protects sensitive information.

Hathority can significantly enhance your supply chain automation by leveraging Boomi’s integration platform to create seamless, end-to-end connectivity across various systems and processes. By utilizing Hathority’s expertise in data integration and process automation, businesses can efficiently synchronize real-time data across ERP, WMS, TMS, and procurement systems, ensuring accurate and up-to-date information flow.